In any manufacturing or warehouse environment, the most valuable insights don’t come from spreadsheets or reports—they come from the floor. This is the central idea behind Gemba, a Japanese term meaning “the real place.” In lean manufacturing, it refers to the spot where value is created. For managers and team leaders, this means spending time at the workstation, observing processes, asking questions, and engaging with the people who do the work.

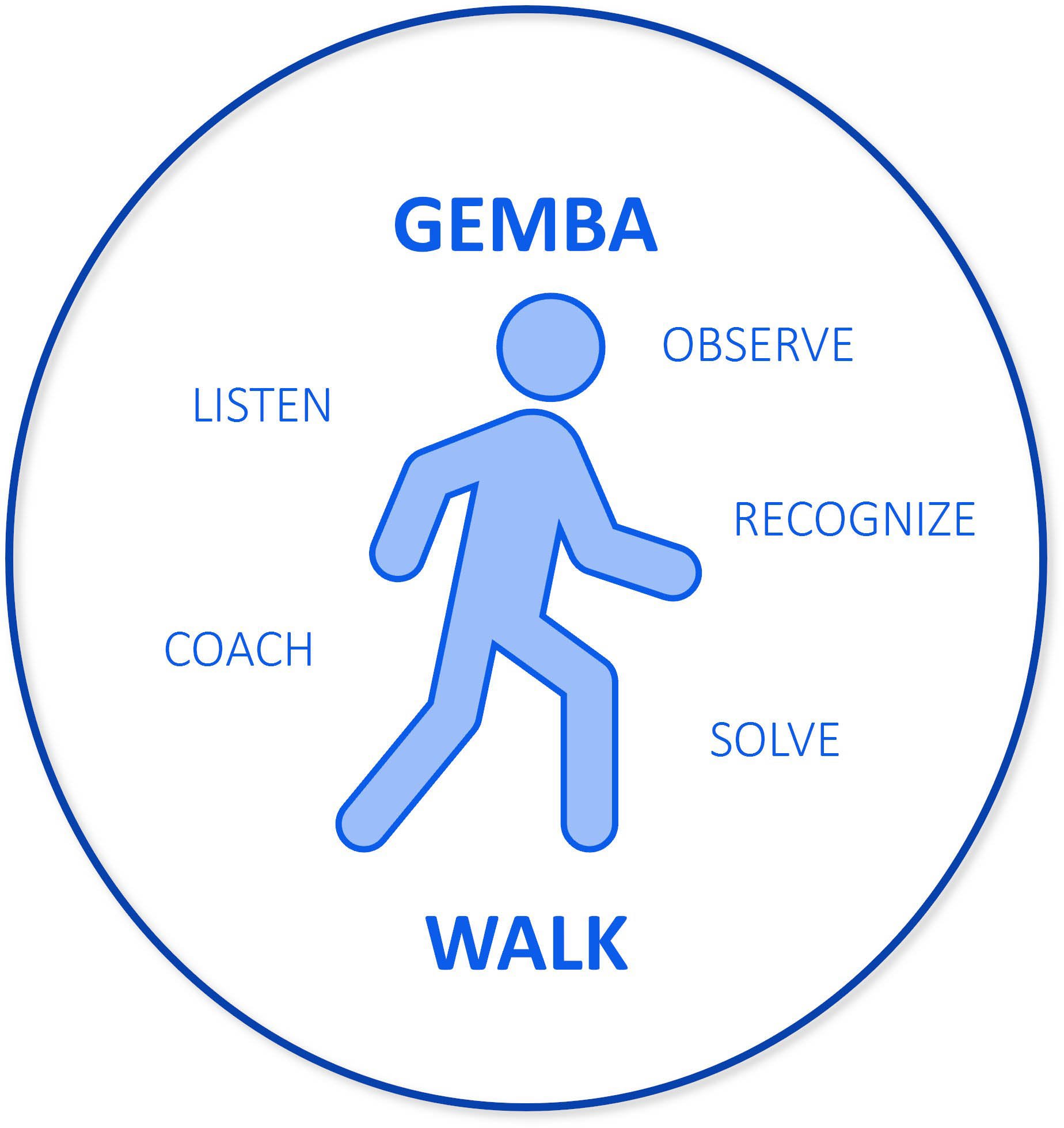

A Gemba Walk isn’t just a casual stroll through the shop floor. It’s a purposeful, structured visit with a clear goal: to identify waste, encourage improvement, and understand the real-world experience of your workforce. When done correctly, it builds trust and drives continuous improvement.

Why Gemba Walks Matter in Workstation Design

The blog by Pucel Enterprises highlights an often overlooked benefit of Gemba Walks—insight into workstation design. Many ergonomic or efficiency problems only become visible when you watch a task being performed repeatedly in a live environment. Gemba Walks allow decision-makers to see how tools are used, how employees move between tasks, and where adjustments can be made to improve safety, flow, and productivity.

For example, a well-designed workstation should minimize unnecessary motion and reduce strain on the operator. But what looks efficient on paper might not translate well to real-world use. Observing how materials are accessed, how equipment is positioned, or how often workers reach or bend can reveal opportunities for improvement that weren’t visible from a distance.

Real Change Starts with Listening

One of the key elements of a Gemba Walk is listening. Employees often have ideas for better layouts or small changes that would make a big difference. By going to the source, asking questions, and showing genuine interest, managers can empower their teams and uncover practical, low-cost improvements.

Integrating Gemba into Continuous Improvement

Whether you’re implementing 5S, Kaizen, or lean warehousing strategies, Gemba Walks should be part of your routine. They help connect leadership to the daily realities of the job and reinforce a culture of engagement and accountability.

If you're evaluating your facility’s layout, redesigning workstations, or launching a lean initiative, start at the source. Walk the Gemba. Watch. Listen. Learn. And improve from the ground up.

Check out our Pucel Products!